Pleasure Boats

As marine specialists, fi innovations can custom make, repair, modify and protect anything nautical. We deal with all manner of recreational powerboats and yachts, commercial vessels, jet-skis, dinghies, kayaks, canoes and stand-up paddleboards, plus we can source the necessary marine parts and accessories.

Whether it’s customising a new boat to meet your needs or breathing new life into an older model, we offer a wide range of solutions. We cater for individual boat owners, manufacturers such as Stabicraft Marine, and tourism fleet owners like Shotover Jet.

A selection of our services:

Modifications

- Hardtops

- Boat lengthening

- Inboard-to-outboard conversions

- Refits

Hull and keel protection

- Carborundum keel strips

- Anti-fouling paint

Repairs

- Transom replacements

- Colour-matched Gelcoat repair

- Re-spray hulls and decks

- Osmosis treatment and repair

- Replace rotten floors and bearers

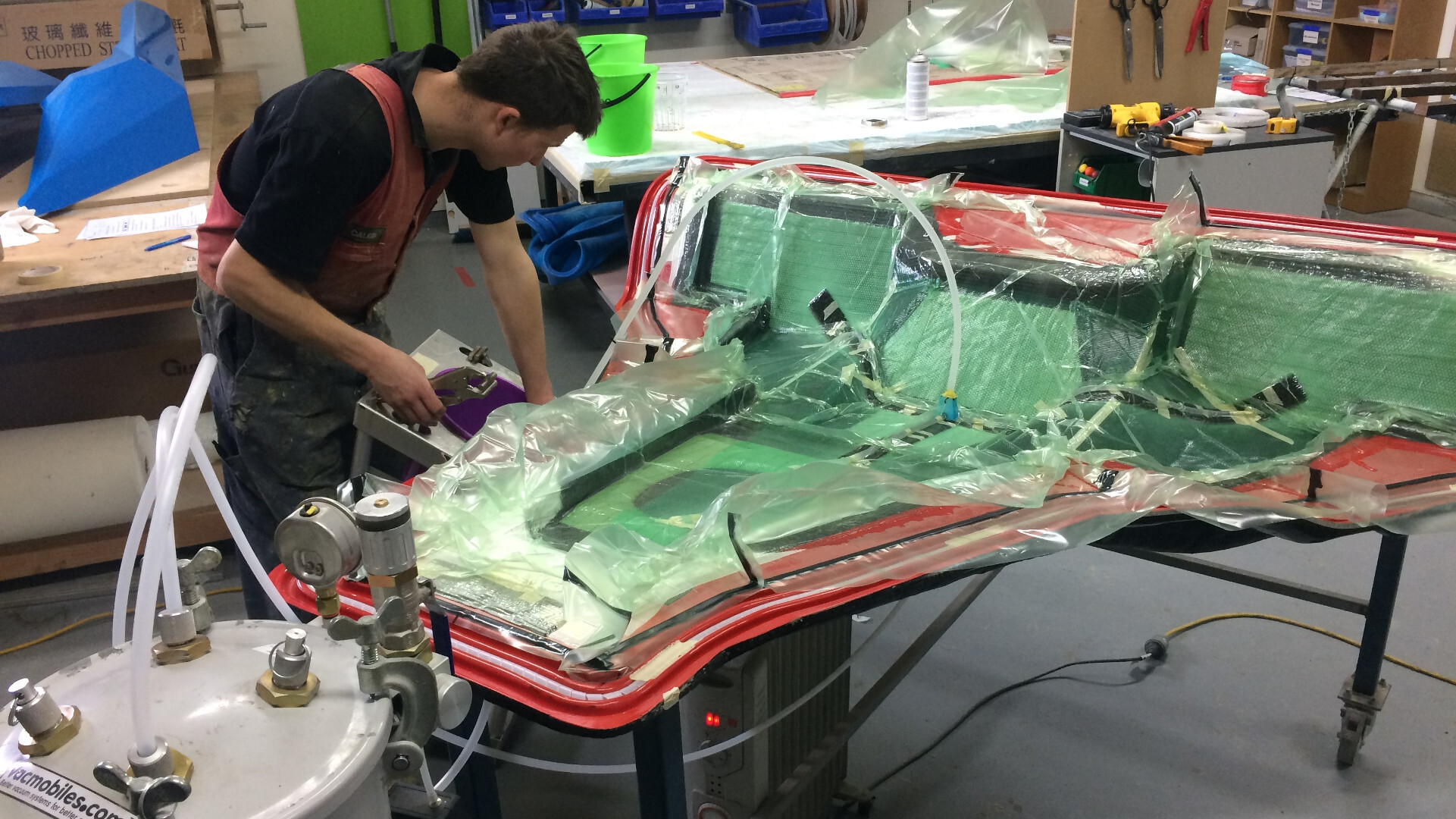

Manufacture

- Battery boxes

- Bait tanks

- Fish chillers

- King/queen seat pedestal

We also have a dedicated foam-filling machine that can inject expanding polyurethane foam into the pontoons and underfloor compartments of boats. This provides greater safety from the increased emergency buoyancy and a quieter ride due to its sound-deadening qualities. Learn more about our Foam services

Services Overview

Services Overview